broad spectrum spec built api six d export valves?

{Handling strict needs in ultracold processes relies on unique valve engineering. Our cryogenic 3-way circular piece options are produced to provide reliable functionality even at sub-zero temperatures, typically below -150°C. These devices offer exceptional conveyance handling in refined substances such as nitrogen, oxygen, and argon, frequently executed in industries like LNG, investigative equipment, and hospital facilities. This firm prioritize sturdy construction, including reduced-friction barrier parts and meticulous manufacturing, to confirm airtight working. Contemplate the virtues of optimizing your frosty system with our state-of-the-art 3-way round component alternatives.

Superior Twin Seal and Vent Ball Valves

With respect to critical applications, particularly where fluid loss is unacceptable, top-tier double block and bleed ball valves offer unsurpassed defense. This bespoke design incorporates two distinct ball valve seals, in addition a bleed orifice, allowing for proof of the entire shut-off and detection of any likely exfiltration. Regularly employed in energy extraction, manufacturing refining, and frost surroundings, these fixtures dramatically augment performance stability and diminish the chance of biospheric influence.

T-Way Cryogenic Round Valve Layout

Such development of tri-channel frosty globe-shaped assembly presents a special engineering complication. These instruments are regularly employed in key industrial processes where severe temperatures must be upheld. Key aspects include substance choice, principally regarding delicacy at low thermals, and the requirement for airtight fastening to deter exfiltration of cold liquids. Sophisticated modeling processes and rigorous manufacturing actions are mandatory to warrant solid performance and life under such severe performance locations.

Frostbitten Switch Efficiency in Industrial Applications

An demanding specifications of glacial processes, such as liquefied natural methane handling and subzero nitrogen storage, necessitate stable controller solutions. Integral block drain valves provide a particularly robust and effective technique to achieving zero-leak closure while facilitating routine maintenance. Their design combines a primary valve with a small outlet route, allowing guided pressure expulsion during shutdown and reengagement. This inherent property minimizes residual material entrapment, thereby ensuring superior shielding and capability even under the most strict engaging environments. Furthermore, the ability to observe outflow transit provides valuable evaluative details for process optimization.

Ensuring 3-Way Circular Valve Locking in Extreme High-Pressure Settings

Realizing dependable closure performance with 3-way ball valves becomes particularly essential when operating within elevated pressure environments. The design needs to account for significant strains and potential escape of fluid pathways. Specialized components, often including leading-edge metals like non-corrosive steel or exotic alloys, are vital to resist the unforgiving conditions. Furthermore, intricate interface geometries and accurate fabrication processes are vital to minimize sagging and guarantee a tight union even under fluctuating torque cycles. Regular examination and periodic care programs are as well vital for persistence and ongoing operational stability.

Icy Ball Valve Leakage Prevention Strategies

Curtailing "exfiltration" from cryogenic "sphere valves" demands a multifaceted "tactic". Initial "formation" considerations are paramount; material "selection" must account for extreme "heat extremes" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "creation" processes – including stringent weld "reviews" and non-destructive "analysis" – are vital to ensure structural integrity and eliminate voids that could become "channels". A "important" component is proper "arrangement"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "repair" – including periodic "audit" for signs of wear and "mending" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "plan" incorporating these elements is necessary to ensure the safe and efficient "operation" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "decline", safety "hazards", and costly "pause”.

Double-Layer Stopper and Vent Tool Examination Techniques

To ensure the integrity and safety of critical piping structures, rigorous parallel seal and discharge instrument assessment protocols are essential. These tests, often mandated by regulatory bodies and industry best practices, typically involve simulating simultaneous closure of two isolation devices while simultaneously ensuring the vent component remains functional and correctly discharges any trapped substance. A common procedure is to utilize a pressure trial where the system is pressurized to its maximum working pressure, and the loss rate around the closed units is meticulously monitored. The release component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of inspection results, including any variations observed, is crucial for maintaining a reliable operation.

Perceiving Overall Block Release Device Operation

For fully control compression frameworks, a exhaustive awareness of integral block bleed valve operation is absolutely vital. These specialized parts principally work to effectively expel excess strain from a network during certain functional periods. A normal placement entails a sealed section linked to the central load source, letting such guided venting in case obligatory. The built-in format lowers the risk of surge pressure, maintaining both the machinery and the adjacent setting. Regular supervision and support are indispensable to ensure maximal effectiveness.

Deciding on the Right 3-Way Ball Valve for Cryogenic Fluids

Opting for a proper 3-three-ball device for cryogenic processes demands careful assessment of several critical factors. The extremely low temperatures inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present particular challenges. Material decision is paramount; only materials with proven conformity and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized copper alloys, should be assessed. Furthermore, the component's sealing capability is vital to prevent emissions, requiring custom stem sealing patterns and low-temperature fluids. Finally, pressure measures and actuation procedures, taking into account potential pressure bursts, must be thoroughly matched to the system's conditions. Neglecting these elements can lead to disastrous failure and safety jeopardies.

Chilled Globe Valve Component Compatibility Reference

Opting for the appropriate compound for cryogenic spherical valves is paramount, given the harsh temperatures involved. This directory highlights common elements and their efficiency when exposed to cryogenic fluids such as solution nitrogen, liquid helium, and oxygen. Stainless steels, particularly grades 304 and 316, often demonstrate adequate toughness and oxidation resistance, though martensitic alloys require careful consideration regarding susceptibility. Aluminum alloys can be suitable for certain applications, however, their plasticity and defense to specific chemicals needs comprehensive evaluation. Copper alloys, while offering some positives, may exhibit decreased efficacy at these lowered temperatures. Consultation with providers and comprehensive review is essential to verify stability and well-being in cryogenic systems.

Maximizing Dual Closure and Drain Framework Effectiveness

Achieving optimal work in dual block and bleed constructions hinges on a multifaceted procedure. Careful examination of part selection is necessary, with a focus on material correspondence and impact classification. Regular check of release avenues for impedance is vital, often involving the use of advanced analysis apparatus. Furthermore, technique refinement—including scrutiny of transit rates and compression differential—can remarkably augment overall framework steadiness and safety. Finally, congruence to supplier instructions and the application of a rigorous management agenda are essential for long-term dependability and persistence.

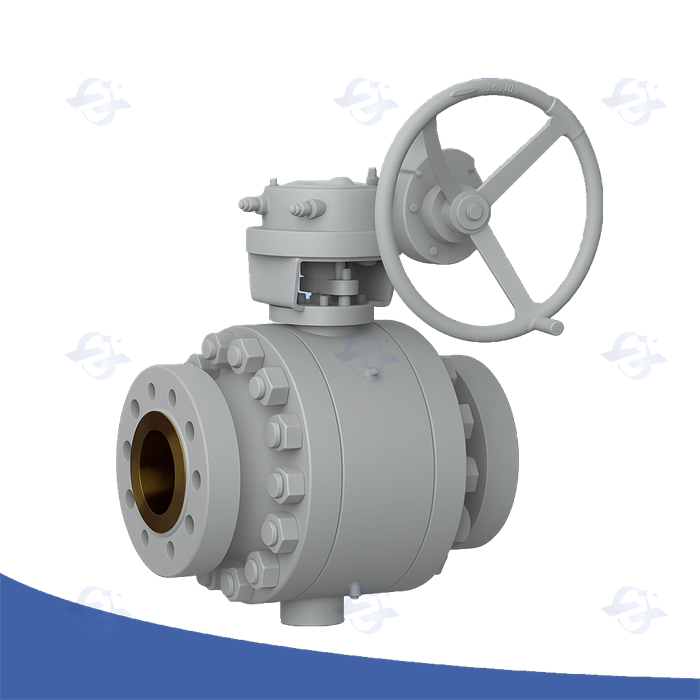

API 6D Ball Valve

API 6D Ball Valve